What are the applications of DC fuse?

TRD-Z DC fuse is suitable for photovoltaic applications with working voltage up to 1000VDC. It can also be used in any other DC circuit

The structural features of the DC fuse

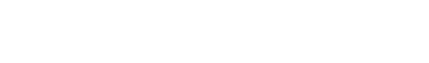

Fuses are mainly composed of 3 parts: melt, shell and support. Melt is the key element to control the fusion characteristics. The material, size and shape of the melt determine the fusing characteristics.

The fuse has the characteristics of reverse time delay, that is, overload current, long fuse time and short fuse time when overload current is large. Therefore, in a certain overload current range, when the current returns to normal, fuses will not fuse and can continue to be used. Fuses have different melting characteristic curves, which can be applied to different types of protected objects. DC fuse

When the melt melts in this section, measures should be taken seriously to analyze the cause of the melting. The possible reasons are:

Short circuit fault or overload operation and normal fusing.

Pay attention to check the N line in the TN grounding system, and the fuse protection device is not allowed on the ground protection line of the equipment.

When the melt is dismantled, it is required to do it:

When the melt is installed, there will be mechanical damage, resulting in smaller cross-sectional area and misoperation in operation. DC fuse

When changing the new melt, check whether the melt rating is matched with the protected equipment. When maintaining the fuses, the power supply should be cut according to the safety regulations, and the fuse tube should not be electrified. DC fuse

Check whether the appearance of fuse (remove fuse tube) is damaged and deformed, and whether porcelain has discharge and flicker marks. DC fuse

Clean the dust and check the contact point of contact point. DC fuse

Fuses should be maintained at the same time as distribution devices:

When replacing the new melt, check the burn condition inside the fusing tube. If severe burns occur, replace the melting pipe. Filler fuses should be filled with filler when replacing melt.

Check whether fuses, melts and protected circuits or equipment match, if there are problems should be promptly investigated.

Before installation of new melts, the cause of melt melts is found, and the cause of fusing is not determined.

When the melt is used for too long, the melt will be broken due to oxidation or high temperature in operation. When the porcelain fused pipe is damaged, do not apply any other material tubes instead.

WeChat public number

WeChat public number

Mobile web site

Mobile web site